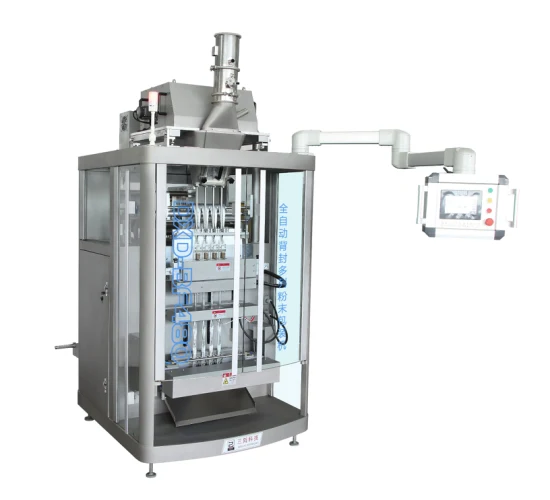

Dovoll Chain Plate Liquid Oil Vat Filling Machine

Overview Package size per unit product 180.00cm * 120.00cm * 70.00cm Gross weight per unit product 300.000kg Product Des

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | FMM-E |

| After-sales Service | Video Technical Support |

| Warranty | 1 Year |

| Type | Count Filling Machine |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding |

| Dosing Device | Capacity Cup |

| Filling Principle | Atmospheric Pressure |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Rotary |

| Packaging | Box |

| Packaging Material | Composite Materials |

| Patent | More Than 70 |

| Machinery Capacity | 4000bph, 100bph |

| Applicable Industries | Food, Beverage, Commodity, Chemical |

| Key Selling Points | High-Accuracy |

| Showroom Location | Yes |

| Machinery Test | Provided |

| Video Outgoing-Inspection | Video Outgoing-Inspection |

| Warranty of Core Components | Provided |

| Core Components | Engine, Bearing |

| Engine, Bearing | CE |

| Selling Units | Selling Units |

| Single Package Size | 2200*900*1600mm |

| Package Weight | 180kg |

| Package Type | Wood |

| Lead Time | 30 |

| Transport Package | Wooden Box |

| Specification | filling labeling capping machine line |

| Trademark | DOVOLL |

| Origin | China |

| HS Code | 8422301090 |

| Production Capacity | 50 |

Packaging & Delivery

Package size per unit product 180.00cm * 120.00cm * 70.00cm Gross weight per unit product 300.000kgProduct Description

This full automatic filling machine is very efficient with high cost performance. 1.Chemicals (medicine oil, medicinal liquor, alcohol, eye drops, syrup,solvent, acetone)2.Oil (edible oil, essential oil) )3.Cosmetics (toner, makeup remover,spray)4. Beverage (juice, fruit wine)5.Seasoning (soy sauce vinegar)6.High and low foam liquid ( Care solution, detergent) 7.This full automatic liquid filling machine is with conveyor and can be used as one part of production line.These are all help you improve working efficiency greatly.Description

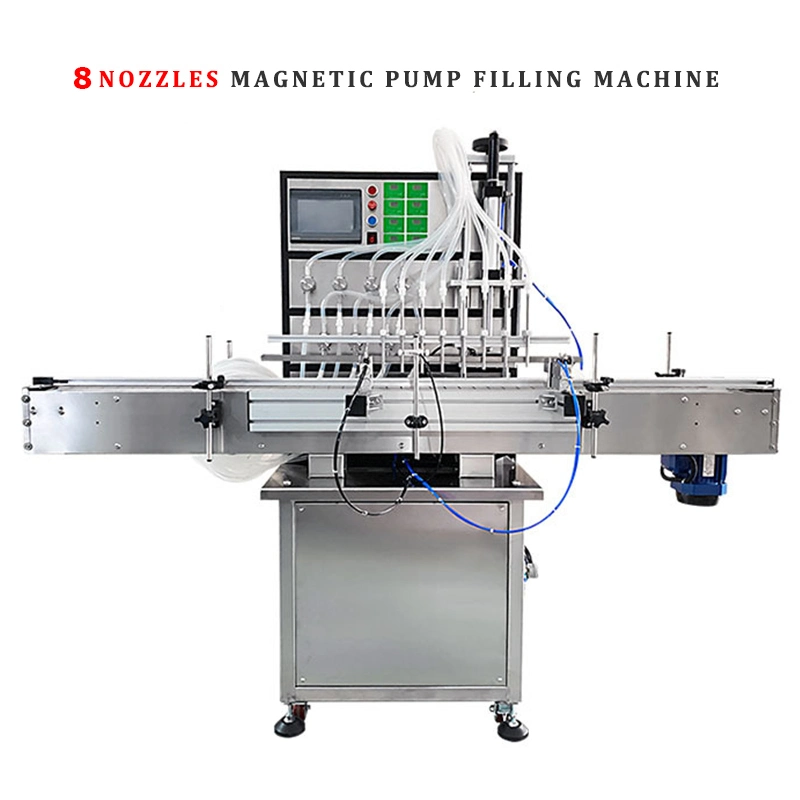

This full automatic filling machine is equipped with pneumatic filling nozzles which is designed for filling thicker liquid like gel,hand sanitizer etc.This powerful magnetic pump makes it can fill material faster,it can realize automated production if work with automatic capping machine and labeling machine.Application

The magnetic pump filling machine is suitable for filling liquid like water,juice,water,essential oil,milk etc.It is widely used in foodstuff,beverage,cosmetics,daily chemical industries.

Product Parameters

| Model: FMM-B | 1 Nozzles | 2 Nozzles | 4 Nozzles | 6 Nozzles | 8 Nozzles |

| Pump | 1. Food grade 316 stainless steel magnetic pump. 2. Corrosion resistance. 3. High temperature resistance (maximum 120°C).4. It can fill liquid and paste (viscosity<3000cps) | ||||

| Voltage Power | 110V--220V 50/60HZ | ||||

| Maximum flow velocity | 5500ml/min (Each nozzle and base on water) | ||||

| Air pressure | 0.3-0.4MPa | ||||

| Working speed | 30-40 bottles/min (based on 10-1000ml filling volume) | ||||

| Count Range | 1-99999 Times | ||||

| Max Suck Distance | 3M | ||||

| Size of air compressor connector | OD8mm | ||||

| Repeat Error | <0.5% | ||||

| Bottle height | <220mm(Customized max height 300mm) | ||||

| Anti-dripping Function | Available | ||||

| Memory Function without Electricity | Available | ||||

| Diameter of Filling Nozzle | φ6mm or φ8mm | ||||

| Package Size | About 2200*900*1600mm | ||||

| Package weight | 140kg | 145kg | 155 kg | 165 kg | 180kg |

A: DOVOLL is a certified manufacturer by Made-in-China and SGS.Q2: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q3: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer 's site to solve any problems.Q4: How could I get the spares on machines?

A:We will send extra sets of easy broken spares and accessories like O ring etc. Non-artificial damaged spares will be sent freely and shipping free during 1 year's warranty.Q5: Is there any insurance which I pay for to guarantee I will get the right machine?

A: Trade Assurance provides quality protection, ontime shipment protection and 100% safe payment protection. Our factory already highest stars of the grade.Q6.What's the payment terms and trade terms for new customers?

A: Payment terms:T/T,L/C,D/P,O/A, Western Union etc.Q7:What's the Minimum Order Quantity and warranty?

A:MOQ:1 setWarranty:12 months,some customized products will be 24 months.Q8:Do I need to pay for the extra cost like tax or duty ?

A:Yes, custom duty / tax it's the buyer responsibility need to pay it, the shipping cost it's not included the tax.

Related Products

-

![S350 Multi Color China Cylindrical Screen Printing Machine Semi Automatic for Perfume Bottle Glass Bottle Plastic Cup]()

S350 Multi Color China Cylindrical Screen Printing Machine Semi Automatic for Perfume Bottle Glass Bottle Plastic Cup

-

![Pharmaceutical Laboratory Hard Gelatin Semi Automatic Capsule Filling Machine (CGN-208D1)]()

Pharmaceutical Laboratory Hard Gelatin Semi Automatic Capsule Filling Machine (CGN-208D1)

-

![PLC Control Semi Automatic Bag on Valve Bov Aerosol Spray Can Filling Machine]()

PLC Control Semi Automatic Bag on Valve Bov Aerosol Spray Can Filling Machine

-

![Automatic Anti-Corroisve Bottle Toilet Cleaner Oblique Neck Bottle Liquid Filling Packing Machine]()

Automatic Anti-Corroisve Bottle Toilet Cleaner Oblique Neck Bottle Liquid Filling Packing Machine