30ml 50ml Automatic Electric Cigarette Oil Capping Machine

Overview 30ml 50ml Automatic Electric Cigarette Oil Capping Machine Product Description Machine name: WB-Y2 / Y4 Automat

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | WB-Y2 |

| After-sales Service | Lifelong |

| Warranty | 1 Year |

| Type | Automatic Filling and Capping Machine |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | SS316 |

| Dosing Device | Peristaltic Pump/Piston |

| Filling Principle | Peristaltic Pump/Piston |

| Structure | Rotary / Linear |

| Packaging | Bottle |

| Packaging Material | Plastic Glass Bottle |

| Machine Name | Wb-Y2 Automatic Filling and Capping Machine |

| Filling Head Number | 2 |

| Adding Plug/Outer Head | 1 |

| Capping Head Number | 1 |

| Filling Volume | 1-150ml |

| Capacity | 5-35 Bottle/Min |

| Filling Accuracy | Less Than 1%(Depends on Product) |

| Pass Rate | Greater Than 98% |

| Powder Supply | 1pH. 220V, 50/60Hz |

| Power | 1.5kw |

| Net Weight | 450kg |

| Overall Dimension | L2200 * W1600 * H1600mm |

| Transport Package | Standard Wooden Case |

| Specification | L2200 * W1600 * H1600mm |

| Trademark | WB |

| Origin | Shanghai |

| HS Code | 8422301090 |

| Production Capacity | 15 Sets/Month |

Product Description

Product Description

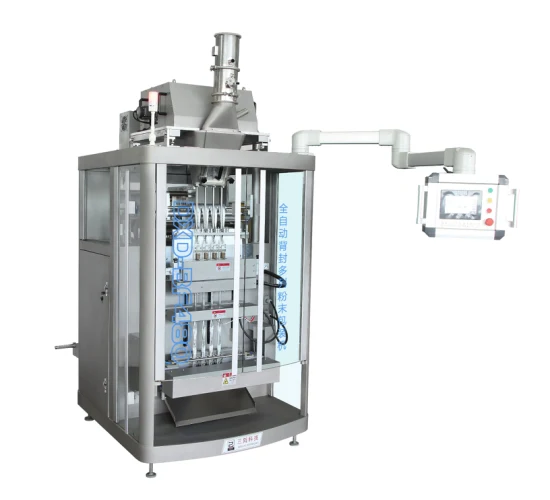

Machine name: WB-Y2 / Y4 Automatic Electronic Cigarette Oil (Eye Drop,Essential Oil) Filling, Plugging in andCapping Machine.

Application: The machine is mainly used for electronic cigarete oil, eye drops, essential oil, nal polish, eye shadowand other products automatically filling, plugging in and screw capping.Performance feature:1, This machine uses mechanical ar to screw caps, eauipped with automatic sliding device, to prevent damace to the cap2. Peristaltic pump or piston pump measuring, (f use piston pump, when the filling volume difference is large, the corre-sponding pump body needs to be replaced), accurate measurement, easy to control.3. Filling system has suction / anti-drip device.4. Color touch screen display, PLC control system, no botle no filing (only peristalic pump) / no adding plug/ no capping.5. Machine shell is made of 304 stainless steel, easy to clean, meets GMP standard.Product Parameters

| Model | WB-Y2 | WB-Y4 | WB-Y8 |

| Filling head number | 2 | 4 | 8 |

| Add plug /dropper head | 1 | 2 | 2 |

| Capping head number | 1 | 2 | 2 |

| Filling volume | 2-200ml | 2-200ml | 2-200ml |

| Capacity | 5-35 bottles/min | 10-70 bottles/min | 20-80bottles/min |

| Filling accuracy | ≤ ±1% | ≤ ±1% | ≤ ±1% |

| Pass rate | ≥ 98% | ≥ 98% | ≥ 98% |

| Power supply | 1ph 220V, 50/60Hz | 1ph 220V, 50/60Hz | 1ph 220V, 50/60Hz |

| Power | 1.5 KW | 1.7 KW | 2.1 KW |

| Net weight | 450kg | 600kg | 700kg |

| Overall dimension | L2200 × W1600 × H1600mm | L2200 × W2000 × H1600mm | L2600 × W2000 × H1600mm |

Detailed Photos

filling nozzle capping part Siemens touch screen adding plug and cap plug and cap feeder finish product with label

Related machine

WB-WZ120 automatic cartoning machine WB-YX2 Automatic Electric Nail Polish Filling, Plugging in and Capping Machine

WB-YX2 Automatic Essential oil Filling, Plugging in and Capping Machine

Company introduction

Contact

Our service

1.Installation and debug:

After customer received machine and placed machine according to layout whichprovide by us, we will arrange technicaian for machine installation, debug and testproduction by two ways:(online teaching,on-site debugging).

2.Training:

We offer technology training to customers.The content of training is structure and maintenance ofmachine, control andoperation of machine. Our technician and salesman will guide and train customeronline, after training, customer's technician could master the operation andmaintenance well.

3.Quality guarantee:

We promise that our machines are all new and never used.Machines are made of suitable materials, adopts new design. Ouality and performanceall meet the requirements of contract.

4.After sale service:

We offer 12 months warranty and wearing parts for each machine, and offer other partsat the lowest price.After customer received machine, if meet any problem during debugor operation of machine, we will help customers online, if the problelms are still can notsolved. or customer need our technician go to their factory, we can arrange it.

FAQ

1: Q:Are you a factory or trading company ?

A: We are a professional manufacturer of Vertical packing machine,horizontal packing and bottle filling machines . At the same time , we are also a trustworthy supplier of other packing equipment ,including tea bag packing machine , wet wipes fold and packing machine , yogurt cup filling and sealing machine , Labeling machine, shrink sleeve labeling machine , box cartooning machine , metal detector, inkjet printing machine , mixing tank and hard candy packing machine and so on .2, Q: Trade assurance order is OK?

A: Sure ,we are happy to conclude trade assurance order, which warranty you quality, on time delivery and payment protection.

3, Q: What is the MOQ ?

A: 1 set .

4, Q: How long is the lead time ?

A : All machine takes around 10-25 days after deposit payment .

5, Q: What is your warranty and after-sale service

A: One year warranty and Lifelong after-sale service via skype/whatsapp/mobile/etc .Also Technical service is available.

6,Q:Can I Visit factory and send team for Learning and inspect?

A:Yes, sure, Welcome your visit and no problem for your team come and learning, we will do our best to teaching they how to use the machine .

7, Q: Which is the nearest sea port for you ?

A : Our company located at Shanghai city ,so Shanghai Port is the nearest port for us . But we can delivery the goods to any port as your request .

8, Q: What advantages we have?

A: Rich experience: We have over 20 years experience in exporting packing machine and bottle filling line , all of our sales have been in packing and filling industry over 20 years , some over 20 years . We have our own experienced engineers in R&D , we keep improving the products quality level , design new and economic products to meet our customers' different requirement . We have our own factory , so that , no matter the packing machine and filling machines which manufactured by ourselves , but also other related machine we get from our partners . All will be re-tested again in our factory .

Related Products

-

![Luye 3 in 1 Automatic Pet Bottle Drinking Water Production Line Beverage Washing Filling Capping Machinery Mineral Pure Water Filling Bottling Sealing Machine]()

Luye 3 in 1 Automatic Pet Bottle Drinking Water Production Line Beverage Washing Filling Capping Machinery Mineral Pure Water Filling Bottling Sealing Machine

-

![Sexbay Medical Silicone New Sex Toy Vibrator for Women]()

Sexbay Medical Silicone New Sex Toy Vibrator for Women

-

![Semi automatic ice cream water liquid honey juice sauce soft drink tomato paste filling machine]()

Semi automatic ice cream water liquid honey juice sauce soft drink tomato paste filling machine

-

![Automatic Antibacterial Disposable 84 Disinfectant Fill Liquid Gel Alcohol Fluid Hand Wash Sanitizer Mixing and Bottle Filling Capping Labeling Packing Machine]()

Automatic Antibacterial Disposable 84 Disinfectant Fill Liquid Gel Alcohol Fluid Hand Wash Sanitizer Mixing and Bottle Filling Capping Labeling Packing Machine