Semi Automatic Gas Aerosol Deodorant Perfume Bottle Sealing Capping Crimping Machine

Semi Automatic Gas Aerosol Deodorant Perfume Bottle Sealing Capping Crimping Machine Perfume filling line is mainly used

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | YD-PM |

| Type | Crimp Sealing Machine |

| Packaging Material Mechanical Properties | Pneumatic |

| Material Type | Liquid |

| Product Name | Perfume Production Line |

| Pressure | Pneumatic |

| Transport Package | Plywood Packing |

| Specification | Customized |

| Trademark | YODEE |

| Origin | Guangzhou |

| HS Code | 841869209 |

| Production Capacity | 200set Per Months |

Product Description

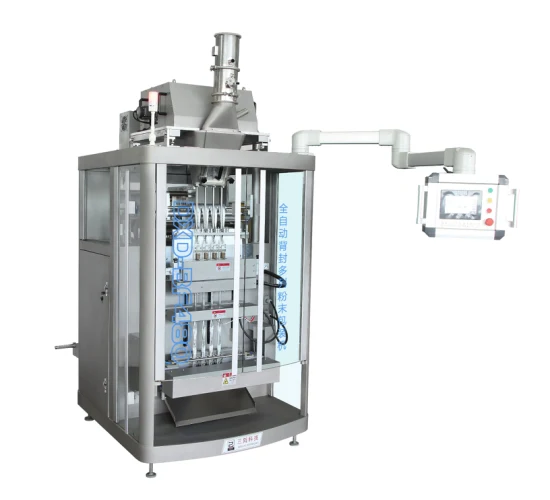

Semi Automatic Gas Aerosol Deodorant Perfume Bottle Sealing Capping Crimping MachinePerfume filling line is mainly used to manufacture perfume. The production line consists of a perfume manufacturing machine, an irrigation machine, and a covering machine. The following is a detailed introduction to each machine. Customers can choose their own production machines according to their needs.

Introduction of Perfume Making Machine

The connecting pipes adopt sanitation grade polishing pipe, most are quick-install connecting way, easy to take apart and clean. Equipped with polypropylene micro porous filtrating membrane which is widely applied in cosmetic industry, research institute, hospital, laboratory etc, to clarify of little fluid and sterilization or chemical analysis, convenient and reliable.

Parameter

| Capacity | 100L | 200L | 300L | 500L |

| HP | 3P | 3P | 3-5P | 5-10P |

| Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Power | 2.2kw | 2.2kw | 3.75kw | 7.5kw |

| Freezing Temperature | -5 Celsius degrees | -5 Celsius degrees | -5 Celsius degrees | -5 Celsius degrees |

| Freezing Medium | R22 | R22 | R22 | R22 |

| Air Source | 0.5-0.6Mpa | 0.5-0.6Mpa | 0.5-0.6Mpa | 0.5-0.6Mpa |

| Filter Pressure | 0.2Mpa | 0.2Mpa | 0.2Mpa | 0.2Mpa |

| Level 1 Filter | 1.0um | 1.0um | 1.0um | 1.0um |

| Level 2 Filter | 0.2um | 0.2um | 0.2um | 0.2um |

Configuration

1. Stainless steel insulating frozen tank and Titanium metal pipe

2. Ultra-low temperature chiller (imported)

3. Antisepsis pneumatic diaphragm pump

4. Polypropylene microporous filtrating membrane

5. Portable stainless steel bracket

6. Sealed electronic control system & sanitation grade pipes and valves

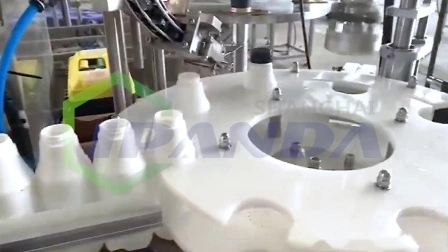

Introduction of Semi Automatic Vacuum Perfume Filling Machine

Parameter

| Filling Head | Four Heads |

| Filling Speed | 10-40bot/min |

| Filling Volume | 5-1000ml |

| Height of Using Bottle Body | ≤250mm |

| Applicable Bottle Diameter | ≤φ90mm |

| Diameter of Bottle Mouth | ≥5mm |

| Filling Accuracy | ±1% |

| Machine Size | 650x650x1650mm |

| Gross Weight | 85kg |

Introduction of Semi Automatic Perfume Capping Machine

1. Compact structure, even closing, good sealing.

2. The cap is positioned accurately and the surface is free of wear.

3. Adopt pneumatic control, easy to operate and maintain.

Parameter

| Applicable bottle size | L: 30-300mm W: 5-100mm |

| Working Method | Pneumatic |

| Capping speed | 10-25bot/min |

| Air Source | 0.4-0.6MPa |

| Torsion | 4-8kg/cm(standard) |

| Mould size | 14 16 19 21mm (Customized) |

| Machine Size | 380x500x700mm |

| Machine Weight | 32kg |

About Yodee

After-sale Service

1. YODEE products will provide a one-year machine warranty service, and accessories will be replaced free of charge.

2. YODEE will provide lifelong machine technical support and technical support services for the later transformation of the old factory.

3. YODEE will provide engineers to guide the installation of equipment and equipment maintenance training services at the customer's factory if necessary.

4. YODEE can accept customer engineers to Chinese factories for equipment training.

Shipment Service

1. If you have a transportation agent, you can directly arrange to come to our company to pick up the goods.

2. If you do not have a transportation agent yet, YODEE will provide you with different ways of machine transportation services (sea, air, express, rail transportation) according to different situations for choice.

3. Under special circumstances, if the machine exceeds the shipping size of the container, YODEE will still plan and provide you with the best shipping plan for you to choose.

Related Products

-

![High-End Quality 510 Vape Cartridge Custom Black Color Vape Pod Filling Machine]()

High-End Quality 510 Vape Cartridge Custom Black Color Vape Pod Filling Machine

-

![Pump Cap Spray Cap Trigger Cap Screwing Cap Capping Machine]()

Pump Cap Spray Cap Trigger Cap Screwing Cap Capping Machine

-

![Full Automatic Tomato Paste Hot Sauce Honey Jar Ketchup Filling Machine, Cream/Peanut Butter/Oil/Jam/Liquid Shampoo Bottling Machiene 3-5% off]()

Full Automatic Tomato Paste Hot Sauce Honey Jar Ketchup Filling Machine, Cream/Peanut Butter/Oil/Jam/Liquid Shampoo Bottling Machiene 3-5% off

-

![Stainless Steel Groundwater Treatment/Borehole Water Filter System/Industrial Filtration System/Water Purifier Machine Price]()

Stainless Steel Groundwater Treatment/Borehole Water Filter System/Industrial Filtration System/Water Purifier Machine Price